Cape's new sewer plant working out 'some bugs'

Like any new system, Cape Girardeau's recently completed wastewater system has a few bugs to work out. Water first was diverted to the new facility in December, several months after the expected date, thanks to persistent wet weather complicating construction...

Like any new system, Cape Girardeau's recently completed wastewater system has a few bugs to work out.

Water first was diverted to the new facility in December, several months after the expected date, thanks to persistent wet weather complicating construction.

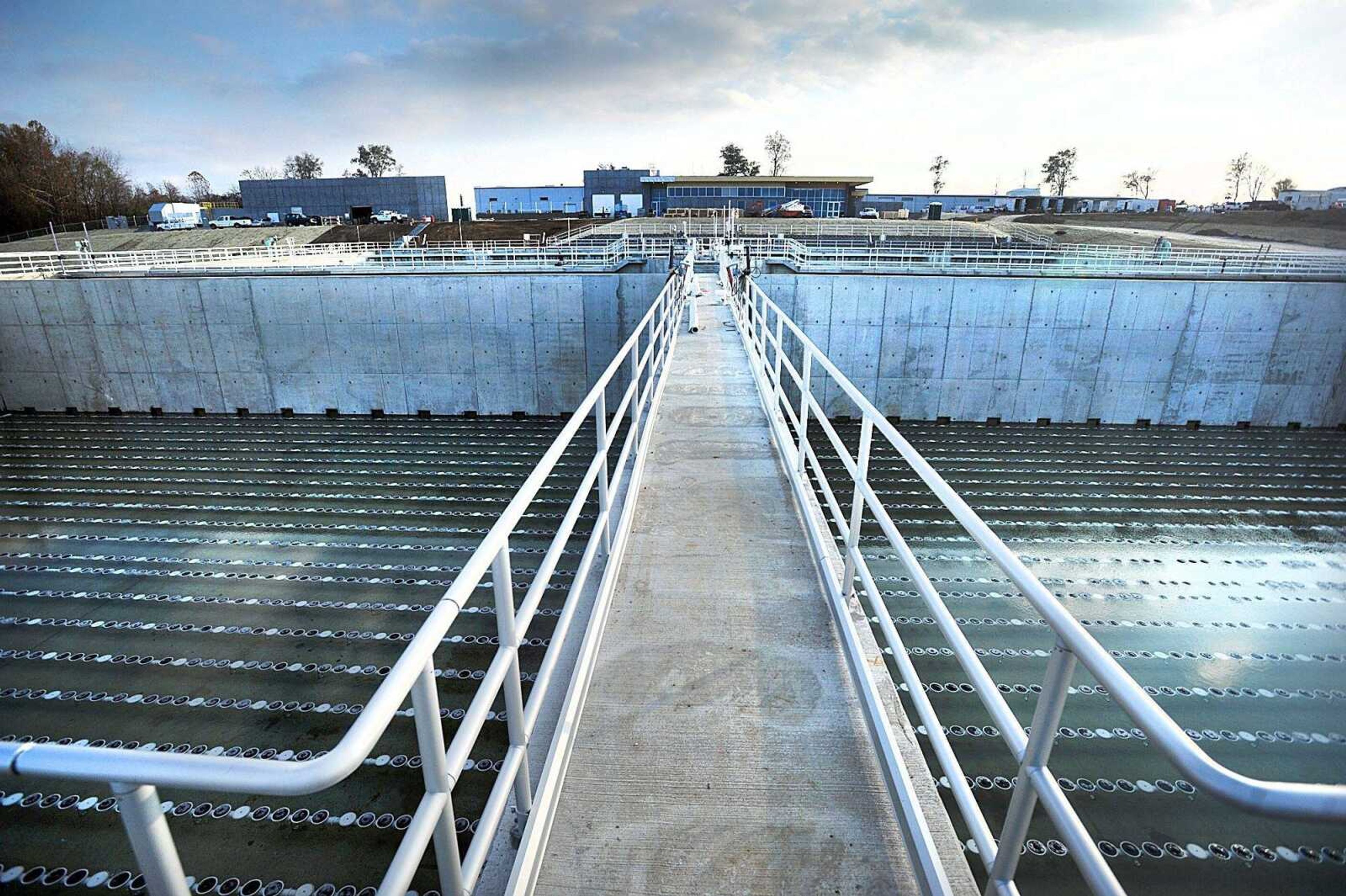

While most processes were operating in December, the full transition was not complete until this year. The facility includes four treatment structures and an administration building, on Corporate Circle near the city's public works station.

One structure includes an ultraviolet disinfection station. It's a more recent treatment requirement handed down by the Missouri Department of Natural Resources and is the final step for Cape Girardeau's wastewater before it hits the Mississippi River. The station was not required to be in operation when water first was diverted to the facility, but public works director Steve Cook said it's running now, as planned.

Laboratory testing of the water was another process that did not begin until this year. The water had to be taken to other nearby facilities for testing, but the lab at Corporate Circle is handling that task as well.

The wastewater plant largely is operating as it should, but crews still are working through a few issues.

"When you're starting up a new facility of this size, you're going to have some bugs to work out," Cook said.

Issues encountered by the city involve odor control and the dryer that helps convert the "sludge" separated from the water into fertilizer pellets. Cook said one of the biggest concerns is moisture development as air moves through the odor control equipment. Taking care of that is a priority before dryer operation begins, he said.

"We're going to install some equipment that will deal with that [moisture issue]," Cook said. "(The Department of Natural Resources), with this being the first dryer in the state of Missouri, is asking several questions about the exhaust, or the air involved in the process. ... We're not going to do anything with the dryer until we're satisfied we're going to meet everything we should meet. There won't be any shortcuts."

For now, the sludge that would normally be dried to become fertilizer pellets is going to a landfill.

Cook said the city has a state-of-the-art facility that residents "can be very proud of," and he looks forward to opening it up for tours when the final issues are resolved. Tours, particularly for students, were frequently given at the old facility on Cooper Street, and he said public works plans to carry on that tradition at the new facility.

The new facility has six pumps and can handle as much as 50 million gallons of water daily. Bouts of consistent rain have put the facility to the test with levels of about 40 million, and Cook said the system handled it well.

"With the old plant, we couldn't handle all the wastewater and had to bypass to the river," he said. "We're not doing that anymore."

srinehart@semissourian.com

388-3641

Pertinent address:

2061 Corporate Circle, Cape Girardeau, Mo.

Connect with the Southeast Missourian Newsroom:

For corrections to this story or other insights for the editor, click here. To submit a letter to the editor, click here. To learn about the Southeast Missourian’s AI Policy, click here.